Recently I needed some copper bus bars for a lithium-ion pack I was building. This pack will be used to power a prototype cooking appliance. But I did not want to buy any pre-made bus bars and decided to try the DIY option.

There is also a video documenting this technique posted down below.

First I found some copper strip that was about .30mm thick. It was sufficient to carry the amperage for testing the pack. I precisely measured and marked the distance for the cells (20ah Lithium Titanate Oxide cells, but it probably doesn’t matter).

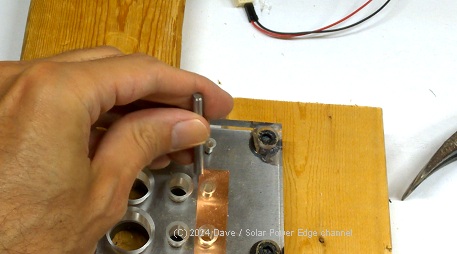

Then I used a “punch and die set” from Harbor Freight to punch round holes in the copper. This tool is something new to me and I struggled at first to use it. After refining the techniques a bit, I started pumping out bus bar after bus bar, more than enough to assemble the battery pack.

A bit of heat shrink or similar material can be used to insulate the middle portion. The result is a neat looking tiny bus bar for very low cost.

The holes punched can be pretty clean if all goes well. Sometimes I had to rework them or flatten the bus bar with a hammer and anvil. That said, with enough practice, this technique has become a new option in the inventory.

I wasn’t very aware of this type of tool, if at all. I’m glad to know about it. Punching instead of drilling can be a great time saver in some cases. On the other

hand, it doesn’t work with thick copper. My attempts at .60mm copper (double stacked .30mm) didn’t go so well, although it was possible to punch through. Three layers did not work at all.

Below are pictures of the battery pack I am building and the bus bars. Trimming the corners with tin snips makes them look a little better and with care, they can be cut with a rounder shape. It’s all a balance of time spent vs. refinement and quality. A better option might be to grind the corners off or use a file, but that takes even more time.

A punch and die set can be found at many tool stores and is apparently very common. I just didn’t know about it.

Hope you enjoyed this article and thanks for reading! -Dave, SPE